Facilities and Equipment

Underground Labs

Y2L

Yangyang pumped storage power plant

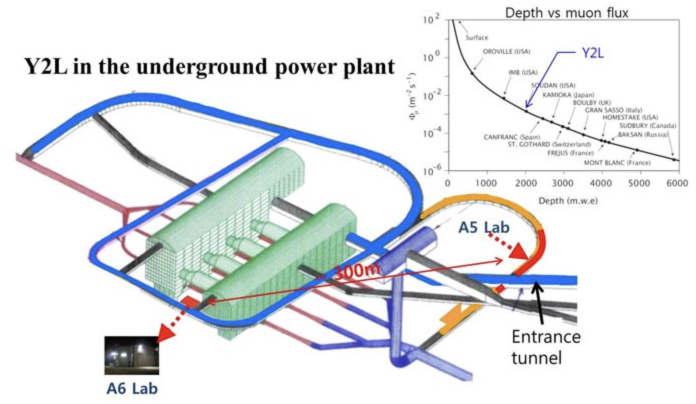

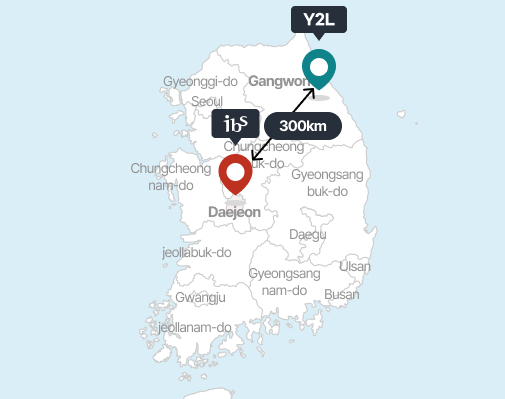

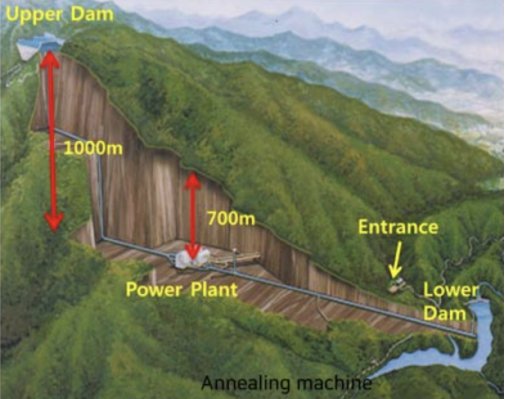

The Yangyang pumped storage power plant (Yangyang plant) located in Yangyang-gun, Gangwon-do is the biggest energy storage plant in Korea. It has 1000 m of water head-height, the highest in Asia as shown Figure 1. The plant is about 300 km from Daejeon, where the IBS HQ is located. Since August of 2006, it started to produce commercial electricity and can produce up to 250 MW using its four turbines at full capacity.

The main facilities of the power plant such as power generation turbines are located at about 700 m below the surface. In the underground, there are several work tunnels (work adits) around the main facilities as well as the main tunnels. The underground experiment group has been maintained one of those work adits called A6 with a generous agreement of the power company who is running the plant. In July 2013, as soon as the Center for Underground Physics(CUP) was started as one of research centers of the IBS, the construction of another small underground experiment facility in the A5 tunnel was started, reaching completion at the end of 2014.

-

Figure 1 :

Location of Yangyang pumped storage power plant (left)

and a schematic drawing of the plant (right).

Y2L-A5 underground facility

In 2003, when the Yangyang power plat was constructed, the Dark Matter Research Center (DMRC) of Seoul National University completed construction of the Y2L-A6 lab site having about 100 m2 area and located at ~700 m depth. In order to directly detect a dark matter candidate, Weakly Interacting Massive Particle (WIMP), in the Y2L they built and operated an experiment with a set of CsI(Tl) detectors. A High Purity Germanium (HPGe) detector system was also constructed and has been operating since.

In the Y2L-A6, it was impossible to expand space further because of topographical constraints. In November 2014, CUP built another underground facility with an area of ~200 m2 in the A5 tunnel, located near the A6 site. This experimental facility is named as Y2L-A5. Right after the Y2L-A5 construction, AMoRE detector (2015), COSINE detector (2016), and a HPGe array (2017) were built subsequently.

The laboratories of Y2L-A6 and A5 are both located at a depth of 700 m. The muon reduction rate, estimated by simulation, is about 10-5 times the surface flux, and the muon flux measured by the COSINE detector at the A5 laboratory is ~4 × 10-3/m2/s. Those numbers are consistent with each other considering that the typical muon rate of ~102/m2/s at the surface. The Y2L-A5 muon rate is also consistent with the measured data at LSC (Laboratorio Subterraneo de Canfranc), one of the world-famous underground facilities. The muon fluxes in different underground laboratories around the world are shown in Figure 2, plotted against the lab depths.

-

Figure 2 :

Layout of the power plant and locations of CUP laboratories,

Muon fluxes in various underground

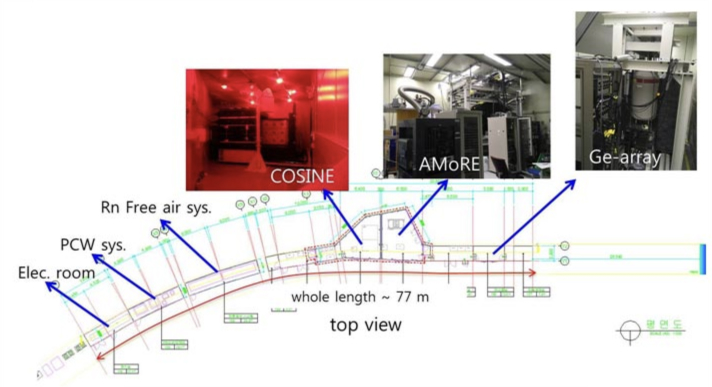

The Y2L-A5 facility consists of two clean rooms and monitoring rooms for each experiment, and several support systems such as a radon-reduction-system, a water-cooling system (PCW), and an electrical room (Figure 3). Also, for the safeties of workers, there are fresh air supply/exhaust system, fire alarm equipment, and a smoke removal system in case of a fire.

Areas of the two clean rooms are 45 m2 and 49 m2 for AMoRE and COSINE experiments respectively. These clean rooms have been maintained as 10,000 class clean rooms with air shower booths and air supplied by dedicated BFUs. In addition, radon free air is supplied to both clean rooms and the air-shower booths from the radon-reduction-system through stainless pipes.

The total electrical power capacity for the Y2L-A5 facility is 180kW which is distributed to each room with 380V and 220V in three phases, and 220 V in single phase. To protect against unplanned outages, an 80 KVA UPS system has been installed to supply all critical powers. The UPS is able to cover power needs for a one-hour outage. Furthermore, for a supply of stable constant voltage, an AVR (Automatic Voltage Regulator) system has been installed.

-

Figure 3 :

Layout of laboratories in Y2L-A5

As mentioned above, the radon-free air system (Figure 4) has been supplying ~120 m3/h of radon-reduced air with about 10,000 of reduction factor. Other significant equipment in the Y2L-A5 includes the Process Cooling Water (PCW) system. In order to cool down the compressors for the AMoRE detector and Radon free air system, 1 ton and 0.5 ton of cooling water is supplied to each per hour.

-

Figure 4 :

Radon reduction system installed at A5 lab of Y2L.

Y2L operation

The ground office with about 80 m2 area is located within 2 km from the entrance of the Yangyang power plant. Three dedicated staff members, including one scientist, monitor and manage the whole facility of the Y2L. When a common emergency occurs, such as a power failure, they not only disseminate information to relevant researchers but also handle the situation themselves if necessary. Especially in case of a serious emergency like a fire, alert systems will automatically notify the Yangyang power plant monitors, the nearest fire station, and the relevant CUP members. However, for certain experiment-wide emergencies, the responsible researchers must respond to the issues.

The AMoRE and COSINE groups dispatch shift workers to Y2L for 24 hours monitoring of their systems to prevent occurrence of unexpected situations. The Y2L is operating based on a systemized management policy that is still being improved, so that measures can be taken immediately.

A part of experiments and facilities in Y2L are going to be moved to a new underground space from 2020, when the new underground laboratory starts operation. Some experiments such as COINE will continue operation in Y2L until 2025.

Yemilab

Motivation

The Y2L-A5 facility was planned only for AMoRE R&D experiments (pilot and phase-I) and not for a full-scale experiment (phase-II). Full size detectors for AMoRE Phase-II, a low-mass dark matter search, and dark-photon experiments require much larger spaces than available at the Y2L-A5. As size of a detector increases, it is natural that scale of the experiment space also increases. According to their plans, it is necessary to have about 600 m2, 250 m2, and 200 m2 areas for AMORE phase-II, a low-mass dark matter search, and HPGe experiments respectively. Additional area of 900 m2 or more is required for coming next generation experiments such as searches for dark matter and dark photons, as well as neutrino experiments. In order to secure such a large space, we studied an expansion plan of the Y2L-A5, but it was not approved by the Yangyang power plant. Thus, we started a systematic search for an alternative location.

Handeok mine

For more than two years, we explored locations throughout the country to find a suitable site for construction of a new underground lab. In early 2016, we decided to choose an active iron-ore mine. The company, Handeok Iron Ore Co., Ltd., is the only iron-ore mining company in Korea at the moment. The mine is located in Jeongseon-gun, Gangwon-do, in the middle of the main mountain range of Korea (백두대간). A construction plan was established in the middle of the same year. We started the construction from September 2017 after making a complete list of all necessary administrative procedures, negotiated one by one. The construction work is currently in progress as planned.

The new underground facility, called as Yemilab, will have 1000 m thick overburden and 3000 m2 size experimental area. It will house experiments that cannot be carried out in the Y2L with its 200 m2 area and 700 m overburden.

Yemilab construction will utilize favorable access features of the Handeok mine. The site has a 600 m deep vertical shaft referred to as “second shaft” (The “first shaft” is older and only 300m deep). As well, it has a 6 km long transportation tunnel (“ramp way”). Existence of these two access routes was a strong motivation in selecting this site. Especially, the second shaft can provide a quick access to/from the underground. The second shaft is expected to work as primary entrance and exit path to/from the underground lab during both construction and operation. Furthermore, we can make the access tunnel shorter for the same overburden when we start the excavation at the bottom of the shaft. This shaft will be one of the most important elements in the new underground facility. The 6 km long ramp way has a 5 m 5 m cross-section providing an alternative path for transporting large equipment that cannot be moved through the shaft.

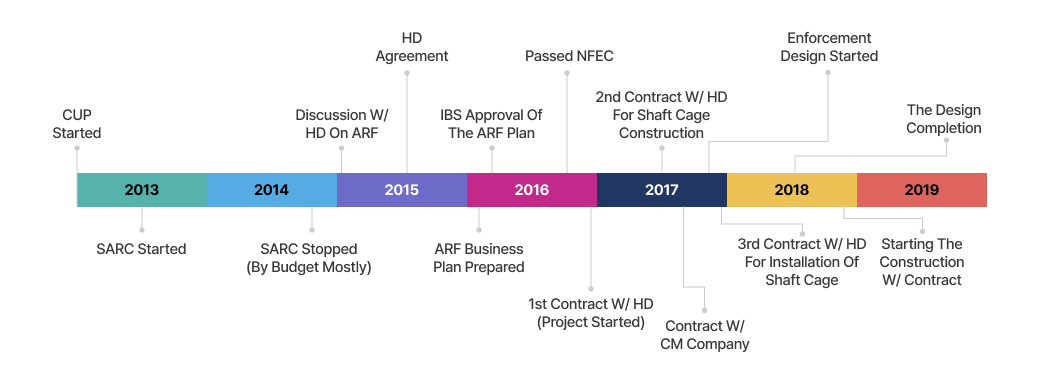

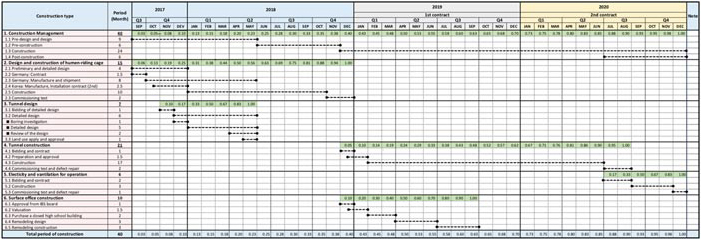

Construction of the Yemilab has started in earnest with an agreement with Handeok in December 2016 (the first contract on construction and operation of the Yemilab). The second contract with Handeok for construction of a cage in the second shaft was made in August 2017, with a contract with CM (Construction Management) for the whole Yemilab construction finalized in September 2017. The third contract with Handeok for construction and installation of the cage was made in December 2017, and a contract for the Yemilab’s working design was signed in December 2017 (Figure 1). The working design is completed in the end of May, 2018. The construction of the cage is going to be completed by the end of 2018.

-

Figure 1 :

Milestones of the Yemilab construction

Construction plan

The Yemilab construction consists of four independent sub-constructions, construction of the shaft cage, excavation of the tunnel, constructions of underground labs and ground office. The cage is one of the basic facilities for accessing the new underground laboratory. It is going to be installed in the second shaft of the Handeok mine, and is under construction now. The cage parts are custom-made by SIEMAG TECHBERG (SIEMAG), a German mine facility company, delivered at the end of June 2018, and installed in the second shaft. SIEMAG is carrying out the design and supervision of the installation, as well as cage production. The major specifications of the cage are summarized in Table 1. Construction of the cage is completed in October 2018, and currently under two months of commissioning operation. It will be in normal operation mode in early 2019.

Table I-10: Basic data for men-riding cage. ML indicates sea level.

| 2nd Shaft | Shaft dimension | D = 6m, L = 627m |

| Shaft top station | +552 ML | |

| Shaft sump | -75 ML | |

| Bottom station | -35 ML | |

| Men-Riding System | Hoisting distance | ~ 587 m |

| Power supply | 440V, 60Hz | |

| Maximum payload | 1,500 kg | |

| Hoisting speed | 4 m/s | |

| Hoisting hours per day | 18 | |

| Working days per year | 300 |

The IBS cage will be operated by a dedicated operator for transportations of researchers and research-related hardwares.

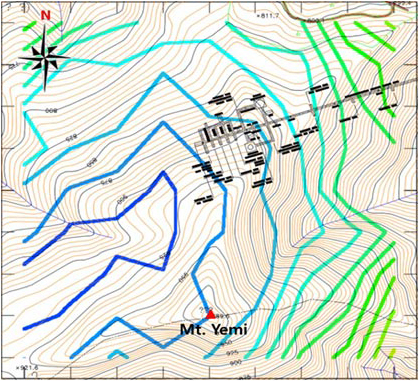

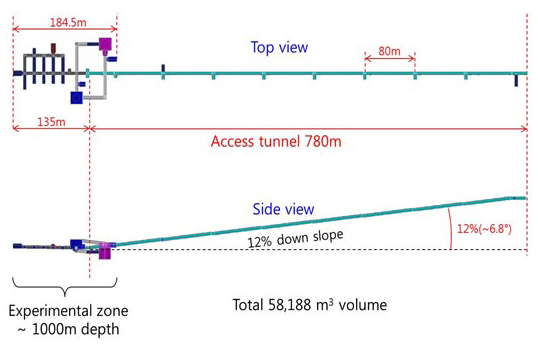

The largest part of the Yemilab construction is tunnel construction. This involves excavating about 57,000m3 of tunnel volume including both the ingress tunnel and the experiment tunnels. The access tunnel starts near the bottom of the second vertical shaft, and will have a length of about 800 m. The basement section will begin at the end of the access tunnel. Volume of the experiment area will be about 25,000 m3; depth is expected to slightly exceed 1,000 m on average. The direction and length of the Yemilab tunnel were determined by simulation studies on muon reduction rates based on a topographical map of the area (Figure 2).

The working design of the tunnel was completed by Sam An Engineering Co., Ltd., selected by a public bidding process, with the design period encompasses 5 months from December 2017 to May 2018.

A conceptual diagram of the tunnel structure was ready on March 23, 2018 as shown in Figure 2. The working design for the construction was confirmed through internal and external review procedures.

-

Figure 2 :

Yemilab tuunel on a muon flux gradient map. The muon flux gradient is calculated by a simulation with a topography of the Yemi mountain. The access tunnel will go along the most effective direction for muon reduction.

-

Figure I-39 :

A layout of Yemilab tunnel.

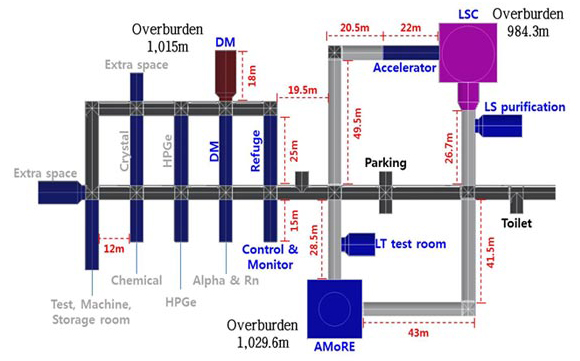

The new underground space will consist of twenty-six laboratories for eight experiments and ten support rooms. Sixteen labs will be constructed as clean rooms of better than class 10,000. An underground experiment facility with a total area of about 9,000 m2 and a volume of 60,000 m3 is scheduled to be completed in the fall of 2020 with anticipated operation of at least thirty years. After the construction is completed, about two to three months of commissioning operation is planned.

-

Figure I-40 :

A design of the Yemilab experiment tunnel.

A roadmap for the construction is shown in Figure 5. Tunnel construction is scheduled to begin by late 2018, and subsequently design orders are being planned for constructions of underground labs and the ground office.

-

Figure 5 :

A roadmap for the construction

Center for Underground

Center for Underground